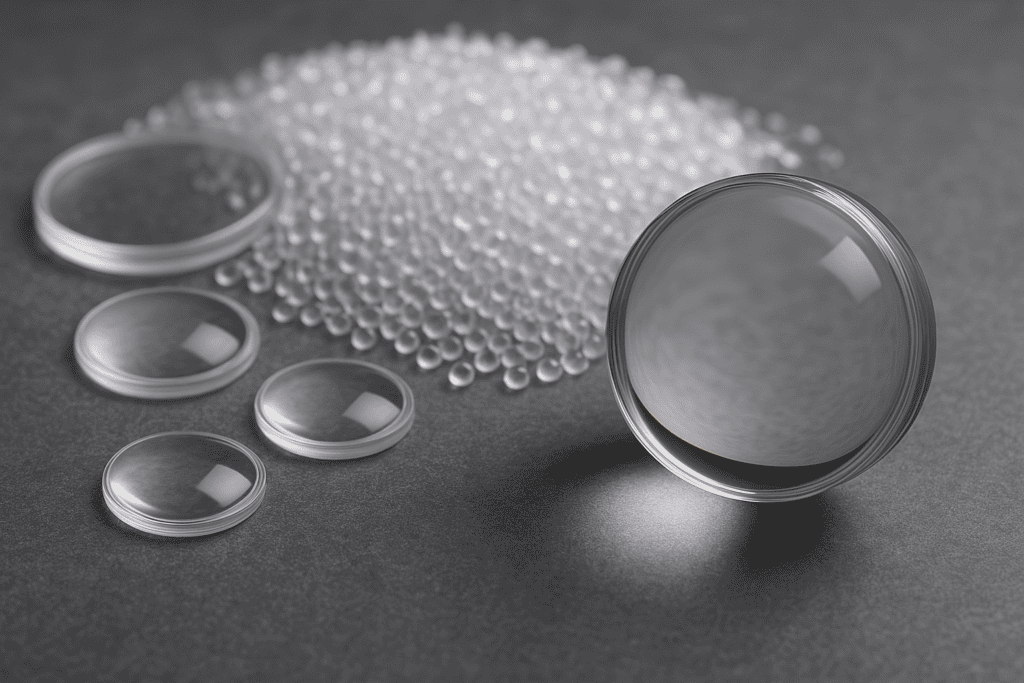

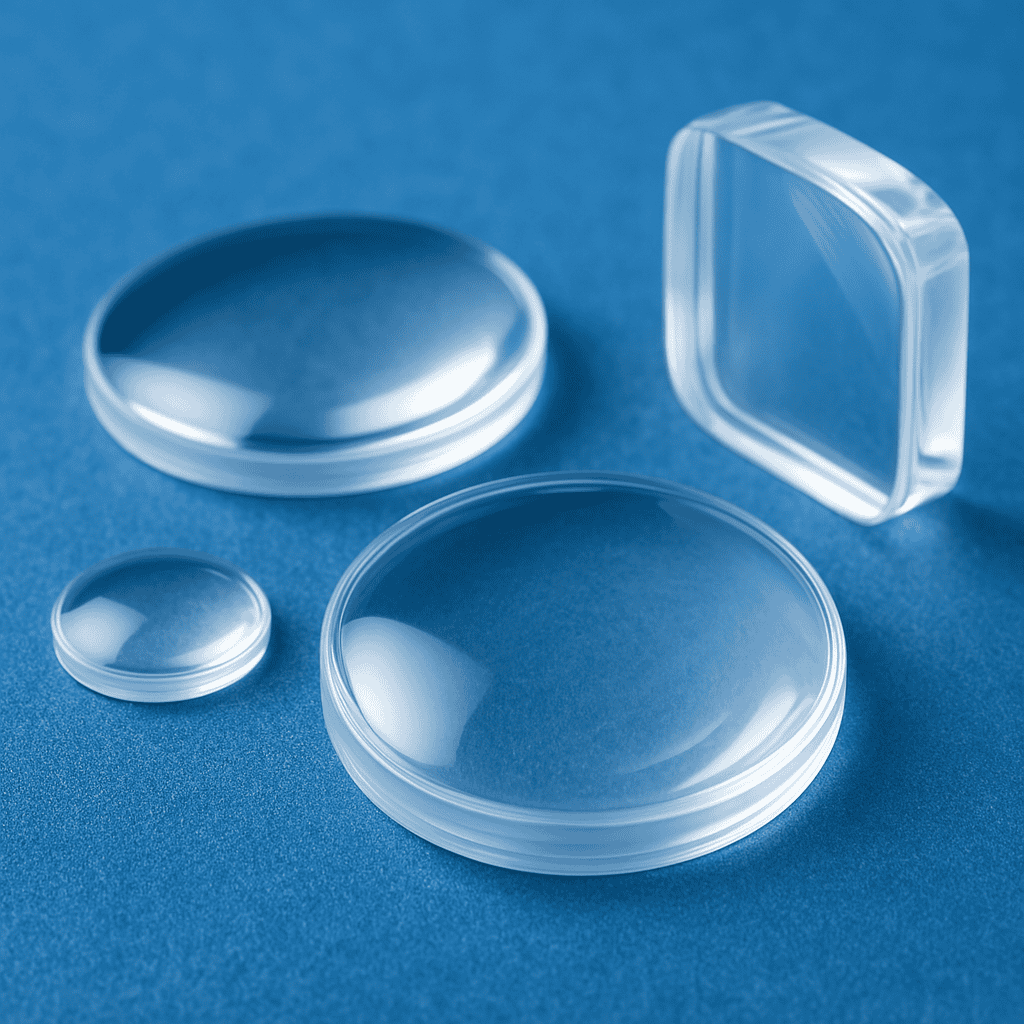

Choosing the right material is a critical step in the development and mass production of plastic optical components. Depending on the application, environmental conditions, and required optical performance, several materials come into play – most notably PMMA, Polycarbonate (PC), COC, and COP.

This article provides an overview of the key properties of these materials and their suitability for different optical use cases.

PMMA (Polymethylmethacrylate)

PMMA, also known as acrylic or under trade names like PLEXIGLAS®, is one of the most commonly used materials in optics. It offers high light transmission (up to 92%), excellent UV stability, and is cost-effective to process.

The refractive index of PMMA is approximately 1.49.

Advantages:

- High optical clarity

- Low water absorption

- Easy to process

- Good weather resistance

Limitations:

- Lower impact resistance compared to PC

- More prone to scratching (requires coating for durability)

Typical applications:

Light guides, optical covers, general optics under low mechanical stress

Material examples:

- PLEXIGLAS® 8N / 7N (Röhm)

- Altuglas® Lenses Grade

Polycarbonate (PC)

Polycarbonate is a tough, impact-resistant material that also provides good optical performance. It is ideal when both durability and transparency are required.

The refractive index of PC is about 1.585.

Advantages:

- Excellent toughness

- Good optical properties

- Heat resistant up to ~120°C

Limitations:

- Higher water absorption

- Slightly lower transmission than PMMA

- Requires UV protection to prevent yellowing

Typical applications:

Lenses in safety equipment, medical devices, outdoor optics

Material examples:

- Makrolon® LED / OD grades (Covestro)

- Lexan® Optical Grades (SABIC)

COC (Cyclic Olefin Copolymer)

COC is a high-performance, transparent plastic offering excellent dimensional stability and minimal moisture absorption. It is suitable for high-precision optics and medical devices.

The refractive index of COC is around 1.53, depending on the grade.

Advantages:

- High optical clarity

- Very low birefringence

- Biocompatible

- Excellent moisture resistance

Limitations:

- Higher cost

- Limited thermal resistance (~80°C)

Typical applications:

Microlenses, disposable medical optics, sensor windows

Material examples:

- TOPAS® COC (TOPAS Advanced Polymers)

COP (Cyclic Olefin Polymer)

COP is similar to COC but provides even better thermal and chemical resistance, making it ideal for high-end optical systems and harsh environments.

The refractive index of COP is typically between 1.53–1.54.

Advantages:

- High transparency and purity

- Thermal resistance up to ~140°C

- Excellent chemical resistance

- High dimensional stability

Limitations:

- Higher price point

- More limited availability

Typical applications:

High-performance lenses, lab-on-a-chip systems, optics in aggressive chemical environments

Material examples:

- ZEONEX® (Zeon Corporation)

- ZEONOR® (Zeon Corporation)

Conclusion

The best choice of plastic optical material depends on your specific application.

- PMMA (e.g., PLEXIGLAS® 8N) is ideal when cost and clarity are key.

- PC (e.g., Makrolon®) suits applications needing high impact resistance.

- COC (e.g., TOPAS®) and COP (e.g., ZEONEX®) are ideal for specialized, high-precision systems where dimensional stability and purity are critical.

Not sure which material is right for your optics project?

Get in touch – we’re happy to support your design and development from material selection to series production.