You can rely on ALL-IN OPTICS for custom, production-ready optical solutions.

From concept to production – we support you with optical design expertise and a strong partner network to deliver functional, manufacturable optical components and systems.

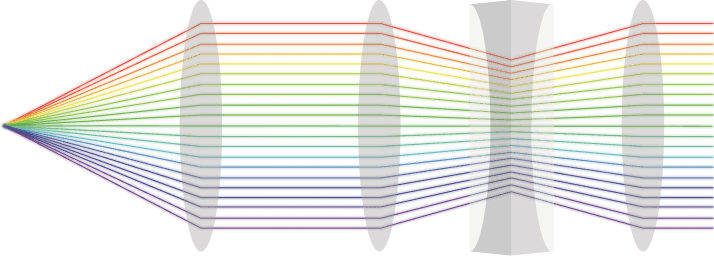

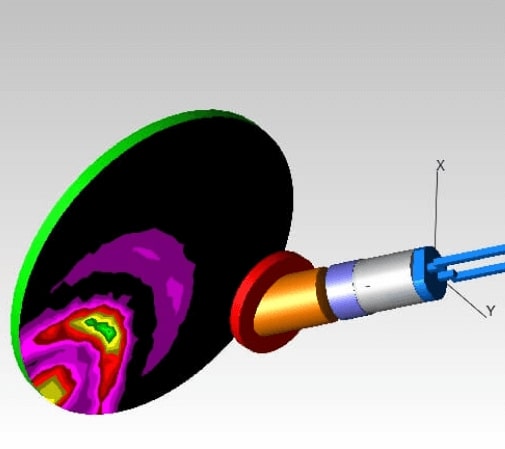

Our expertise includes optical design for

Diffractive optical elements

Aspherical or spherical

Refractive or reflective

Freeform surfaces

The workflow

From Idea to Manufacturable Optical Design

Most optical projects start with a product idea – and the optical design is often the first and most critical step toward a mass-produced optical part or system.

Starting with a well-thought-out optical concept helps to avoid late-stage redesigns and unnecessary costs. A solid design early on prevents surprises when the product is already close to production.

Key Questions We Help You Answer:

Is the available space sufficient to achieve the desired optical performance?

How many lenses are required for my endoscopic system?

Which LEDs should I use – and how many?

What tolerances will affect my injection-moulded part?

What We Offer:

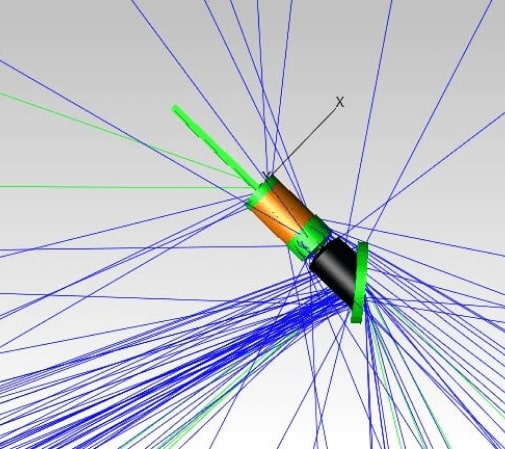

Initial optical calculations based on your specifications

Feasibility studies: what’s possible, and what’s not

Comparison of multiple design options to find the best fit

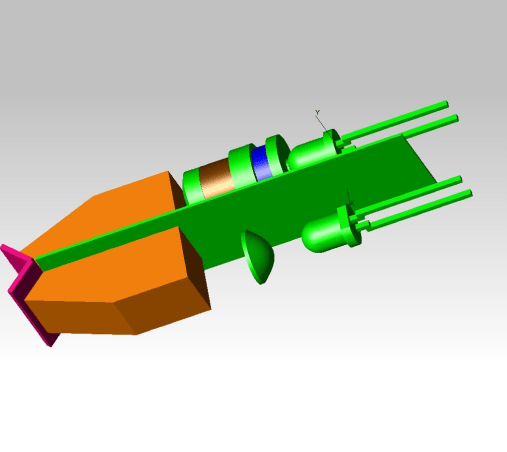

Optimization of the chosen concept and transition to a solid CAD model

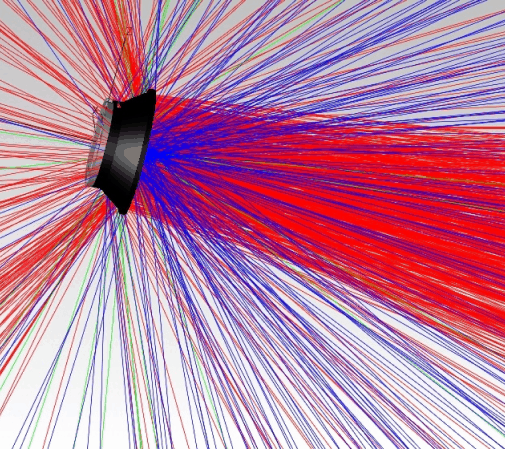

Integration of manufacturing tolerances for plastic injection moulding

From Design to Prototyping and Beyond

Initial optical calculations based on your specifications

Feasibility studies: what’s possible, and what’s not

Comparison of multiple design options to find the best fit

Optimization of the chosen concept and transition to a solid CAD model

Integration of manufacturing tolerances for plastic injection moulding

Once the optical design is finalized, we’ll review and discuss the results with you. Then we support your journey toward a final, manufacturable product.

Thanks to our expertise in injection moulding of plastic optics, we help adapt your design to real-world production constraints – ensuring both functionality and efficiency.

Additionally, we’ll provide a quote for prototyping, allowing you to validate your optical design before moving into full-scale production.