Injection Moulding of Plastic Optics

The Basics

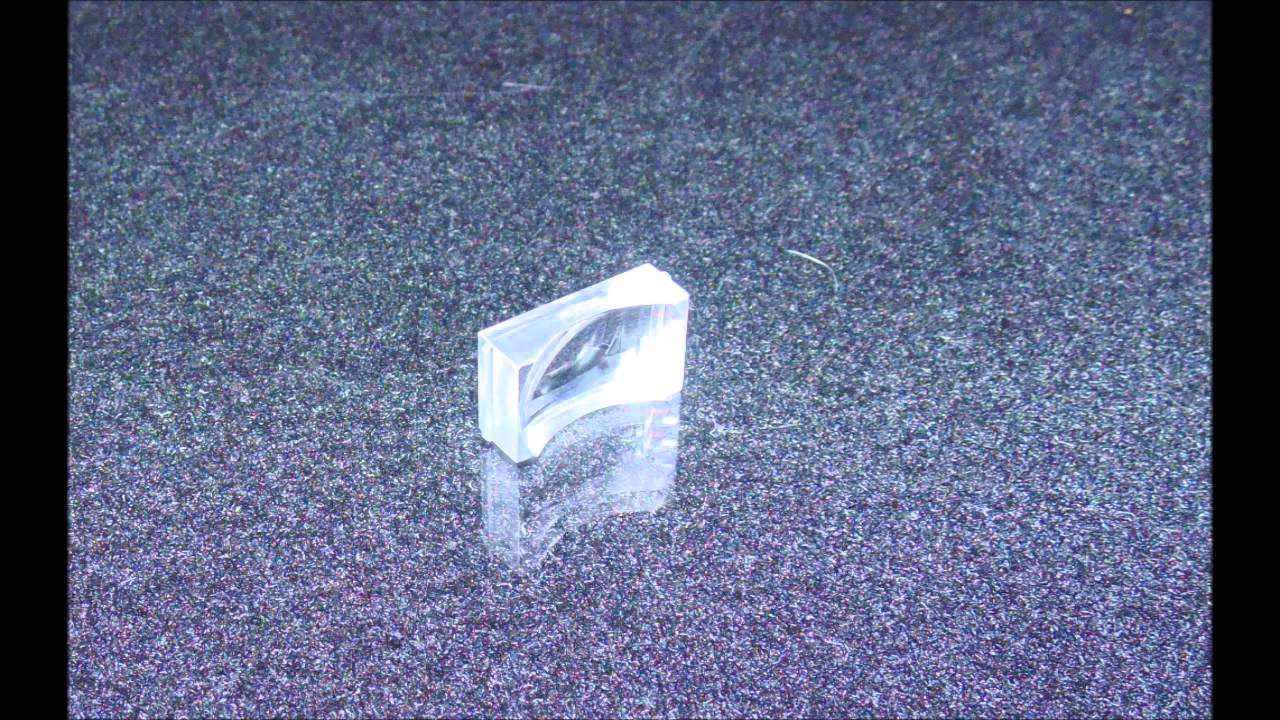

Injection moulding in the context of plastic optics is one of the most, if not the most, efficient method for reproducing optics particular those with intricate surface geometries. The injection moulding machines available are specifically designed to be able to produce and reproduce accurately optics. This brings us to the Fresnel Lens.

Fresnel Lenses – History

Fresnel lenses were created back in the 19th Century by French physicist Augustin-Jean Fresnel. The primary use for these lenses were for use in lighthouses, which is believed to have saved millions of ships since creation. The purpose behind the creation of the Fresnel lens was due to the application in which it was used. Using a traditional magnifying lens, the taper from the thick centre to the outer edges is what generates the magnification. For use in a lighthouse, this would not be practical as the size, weight, and ability to mount a traditional lens would have been impossible at the time. The design of a Fresnel lens allows a drastically thinner and lighter lens to be used however at the cost of image quality due to spherical aberration, but in the application of magnifying light at a lighthouse, the image quality is irrelevant. Fresnel lenses are designed with concentric rings, each being slightly thinner than the next which focuses light to the centre with the angle of each ring’s face being different.

Fresnel Lenses – Modern Day

Several hundreds of years later and the Fresnel lens can still be found commonplace all around the world. It serves many different purposes as a cost-effective method still to this day. Some of the more common uses include traffic lighting, cathode-ray tube displays found in televisions and computer screens (although technology is advancing away from these), rear view vehicle mirrors, and in photography, particularly by Canon and Nikon as they have used Fresnel lenses to reduce telephoto lens sizes.

Fresnel Lenses – Future

They are likely to be used increasingly in the future too, as developments with solar power can greatly use the effects of Fresnel lenses as they are able to concentrate sunlight to solar cells with a ratio of almost 500:1, allowing the active solar cell surface to be reduced. With injection moulding we can offer a variety of different optic lens services, whether it be prototyping or manufacturing. Modern day technology combined with the original development of the Fresnel lens has allowed a great technological advancement with lighting and other optics. Get in touch with us today to see how we can assist your next project.