Glass vs. Plastic Lenses: When to Choose Which – A Practical Comparison

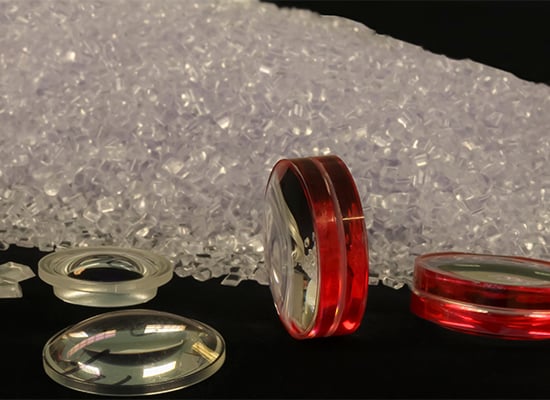

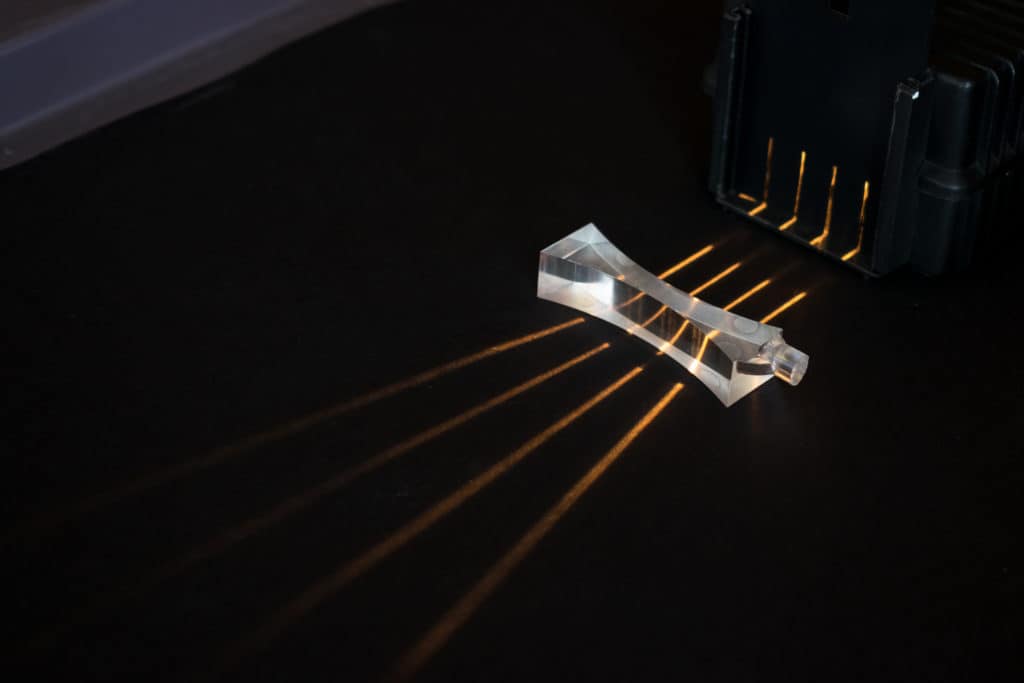

When it comes to optical system design, one of the most fundamental decisions is the choice between glass lenses and plastic lenses. While both technologies offer excellent performance under the right conditions, the trade-offs in cost, manufacturability, and application suitability can be significant. In this article, we compare both materials using a practical example – […]

Glass vs. Plastic Lenses: When to Choose Which – A Practical Comparison Read More »